1 Dental CAD/CAM: The future of dentistry - everything you need to know

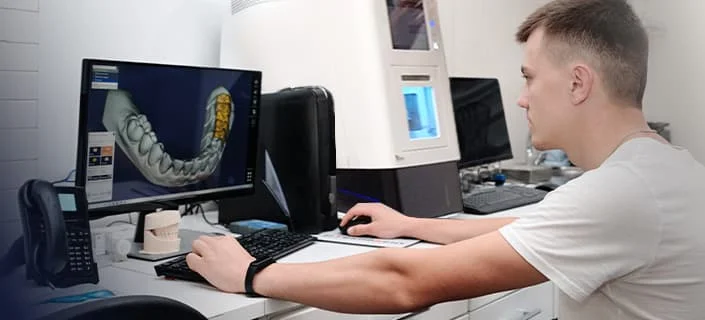

The dental industry has seen significant technological advances in recent decades, particularly with the introduction of CAD/CAM systems. These technologies have not only revolutionized the way dental treatments are carried out, but have also significantly improved the efficiency and accuracy of these procedures.

Dental CAD and CAM make the production of dentures much easier for patients, dentists and dental technicians. Patients no longer need an unpleasant impression, and automated production makes dentures more cost-efficient. The workload for dentists and dental technicians is reduced. The end product includes highly compatible and tooth-colored implants, crowns, bridges and inlays, made from high-quality materials such as zirconium dioxide, titanium, ceramics and special plastics.